Expansive Potential of 3D Printing

The Health Care Sector has witnessed remarkable advancements over the years, and one of the most transformative technologies in recent times is 3D printing. 3D printing, also known as additive manufacturing, has revolutionized the healthcare sector by enabling the production of highly customized and intricate medical devices, prosthetics, anatomical models, and even human organs. This article explores the significant scope of 3D printing in the Health Care Sector and its potential to reshape healthcare delivery.

What is 3D printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering or adding materials one layer at a time. It involves using a 3D printer that follows digital instructions to build the object layer by layer, based on a computer-aided design (CAD) model. The printer deposits or solidifies materials, such as plastic, metal, or resin, in a precise manner, forming the desired shape. 3D printing offers numerous advantages, including the ability to produce complex geometries, customization, rapid prototyping, and reduced material waste compared to traditional manufacturing methods. It finds applications in various industries, including healthcare, aerospace, automotive, architecture, and consumer products, enabling innovation and creativity in design and manufacturing processes.

Commonly used 3D printing methods

There are several common types of 3D printing methods, each with its own unique approach and characteristics. The most commonly used 3D printing methods include:

Fused Deposition Modeling (FDM): Uses thermoplastic filament to build objects layer by layer.

Stereolithography (SLA): Solidifies liquid resin with a laser to create highly detailed prints.

Selective Laser Sintering (SLS): Fuses powdered materials with a laser to produce functional parts.

Digital Light Processing (DLP): Cures liquid resin with a digital light projector for faster prints.

Selective Laser Melting (SLM)/Direct Metal Laser Sintering (DMLS): Melts metal powder with a laser to create metal parts.

Binder Jetting: Uses a liquid binding agent on powdered materials to build objects rapidly.

Extensive scope of 3D printing in the healthcare sector

Medical Device Customization: 3D printing enables the production of patient-specific implants, prosthetics, and surgical instruments, improving treatment outcomes and reducing complications.

Surgical Planning and Training: Anatomical models created through 3D printing assist surgeons in preoperative planning, enhancing surgical precision and reducing operation time. Medical students also benefit from realistic models for training purposes.

Biofabrication and Organ Transplants: 3D printing is advancing the field of tissue engineering, with the potential to print functional human tissues and organs. Although still in the experimental stage, this technology has the capacity to address organ shortage issues and revolutionize organ transplantation.

Prosthetics and Orthotics: 3D-printed prosthetic limbs and orthotic devices offer greater customization, faster production, and improved affordability, increasing accessibility for patients in need.

Pharmaceutical Applications: 3D printing allows for the production of personalized drug dosages and complex drug delivery systems, enhancing treatment efficacy, reducing side effects, and improving patient compliance.

Surgical Guides and Implants: 3D-printed surgical guides assist surgeons in performing precise procedures, while patient-specific implants improve the fit and functionality of medical implants.

Dental Applications: 3D printing has found widespread use in dentistry, including the production of crowns, bridges, and aligners. It enables faster and more accurate dental restorations.

Medical Education and Research: 3D printing facilitates the creation of anatomical models for medical education and research purposes, providing hands-on learning experiences and aiding in the development of new medical techniques and procedures.

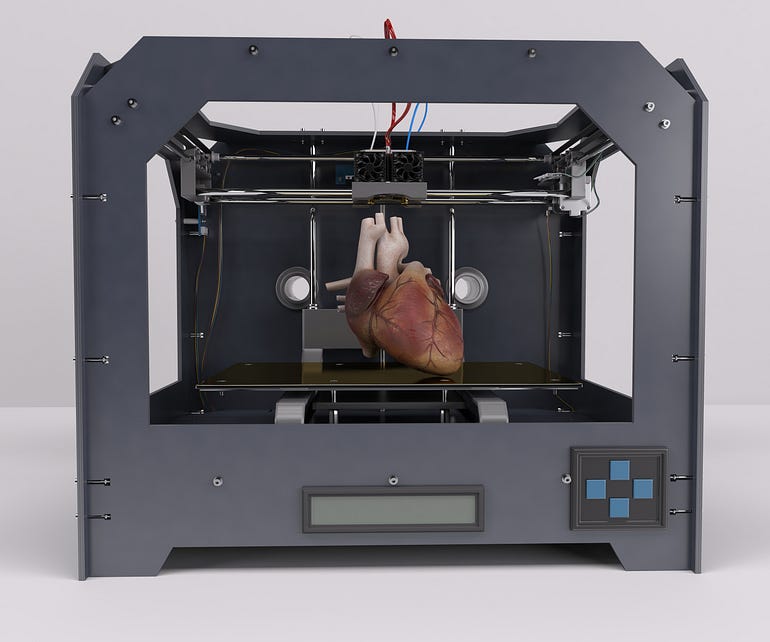

Bioprinting or 3D printing of human organs

The 3D printing of human organs, also known as bioprinting, is an emerging field that aims to create functional human organs using a combination of living cells, biomaterials, and 3D printing technology. While it is an area of active research, it is still in the early stages of development and faces numerous challenges. Here are some key points regarding the 3D printing of human organs:

Bioinks: Specialized bioinks are used in bioprinting to serve as the “ink” containing living cells. These bioinks should support cell viability, promote cell growth, and possess appropriate mechanical properties to mimic the native tissue environment.

Cell Sources: Cells for bioprinting can be derived from various sources, including patient-specific cells, stem cells, or cell lines. The choice of cell source depends on factors such as compatibility, functionality, and the ability to proliferate and differentiate into specific cell types.

Printing Process: Bioprinting involves depositing layers of bioink containing cells using a 3D printer. Multiple printing techniques, including extrusion-based, droplet-based, and laser-assisted methods, are being explored to achieve precise layering and cell placement.

Vascularization: Creating a functional vascular network is crucial for larger organs to ensure proper nutrient supply and waste removal. Researchers are actively investigating strategies to incorporate blood vessels into bioprinted tissues, such as using sacrificial materials or promoting angiogenesis post-printing.

Tissue Maturation: Bioprinted organs need to undergo maturation to develop functionality similar to native organs. This process involves providing appropriate environmental conditions, such as supplying nutrients, oxygen, and growth factors, to support cell growth, tissue development, and functional integration.

Ethical and Regulatory Considerations

The ethical implications of bioprinting, including sourcing of cells, use of animal models, and potential misuse of the technology, need to be carefully addressed. Regulatory frameworks must be established to ensure safety, efficacy, and quality control of bioprinted organs before they can be used for transplantation.

While significant progress has been made in bioprinting simpler tissues and organoids, such as skin and cartilage, the bioprinting of complex, fully functional human organs like the heart or liver remains a considerable challenge. Extensive research and collaboration across disciplines are required to overcome these challenges and realize the potential of bioprinting for organ transplantation, ultimately offering new hope for patients in need of organ replacements.

Author –Ragesh R

IT professional specialized in healthcare technologies with over two decades of experience. He also has a fondness for photography, traveling, designing, painting, and sharing knowledge.